Product Description

The water bottle filling plant is mainly applied for the filling of beverage. Integrating with washing, filling and sealing, it realizes full automation in the whole process, suitable for polyester bottle and plastic bottle filling of mineral water and purified water. The bottle types applicable for various parts are easily, conveniently and rapidly adjustable. It adopts new micro-negative pressure filling, stable and reliable. Compared with the machines of the same specification, the benefit of this machine is larger. The machine adopts advanced OMRON programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectrical inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

Mineral Water Bottle Packing Machine Features

- This Water Filling Machine adopts advanced human-machine interface control. High quality international name brand key components.

- Suspension bottle neck catcher structure allows the machine change the bottle type easily. By changing the valves, it also can be used as Hot Filling Machine.

- Spring type rinsing catcher can wash both inside and outside of the bottle.

- High accuracy pressure water filling mechanism, ensure the height and quantity of the water filling.

- Magnetic powered cap device ensures tightness and prevents damage of the caps.

- Quiet, rotary cap unscrambler will not damage caps. Photoelectric sensor detect missing caps thus eliminating uncapped bottle spillage.

- Built-in safeguard mechanism ensures the safety of operator and machine.

- High efficient air clean filter system ensures high sanitary requirement.

- Low overall machine noise.

- Self-lubricating system imported from America provides continuous smooth operation.

Technical Parameter

| Model | CGF 40-40-12 |

| Washing workstation | 40 |

| Filling workstation | 40 |

| Capping workstation | 12 |

| Production capacity(500ml)(B/H) | 16000-20000 |

| Suitbale bottle specification(mm) | Φ=50-100, H=170, Volume=330-2250ml |

| Motor power(KW) | 7.5 |

| Overall dimension(mm) | 4600×2800×2900 |

| Weight(kg) | 8500 |

Other models

| Model | Washig heads | Filling heads | Capping heads | Production B/H |

| CGF883 | 8 | 8 | 3 | 2000-3000 |

| CGF14125 | 14 | 12 | 5 | 3000-4000 |

| CGF18186 | 18 | 18 | 6 | 5000-7000 |

| CGF24248 | 24 | 24 | 8 | 8000-12000 |

| CGF323210 | 32 | 32 | 10 | 12000-15000 |

| CGF505012 | 50 | 50 | 12 | 20000-24000 |

| CGF606015 | 60 | 60 | 15 | 25000-30000 |

| CGF808020 | 80 | 80 | 20 | 35000-40000 |

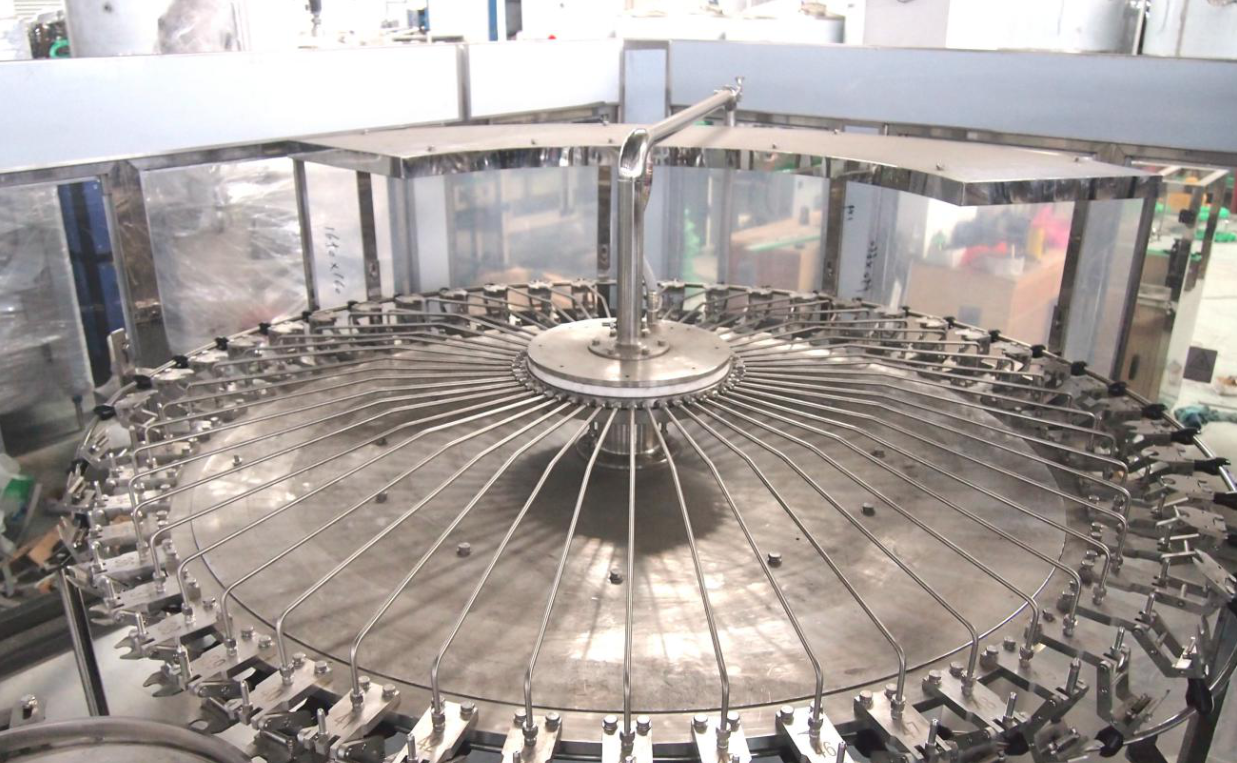

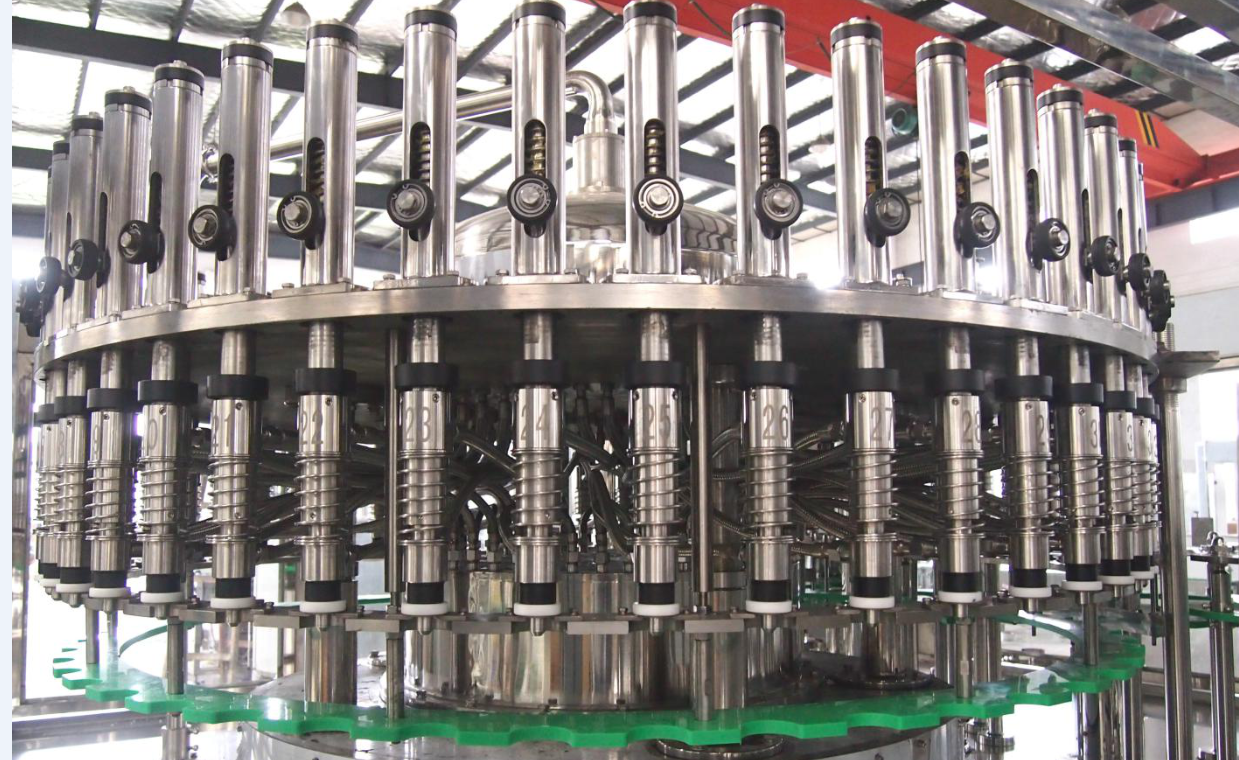

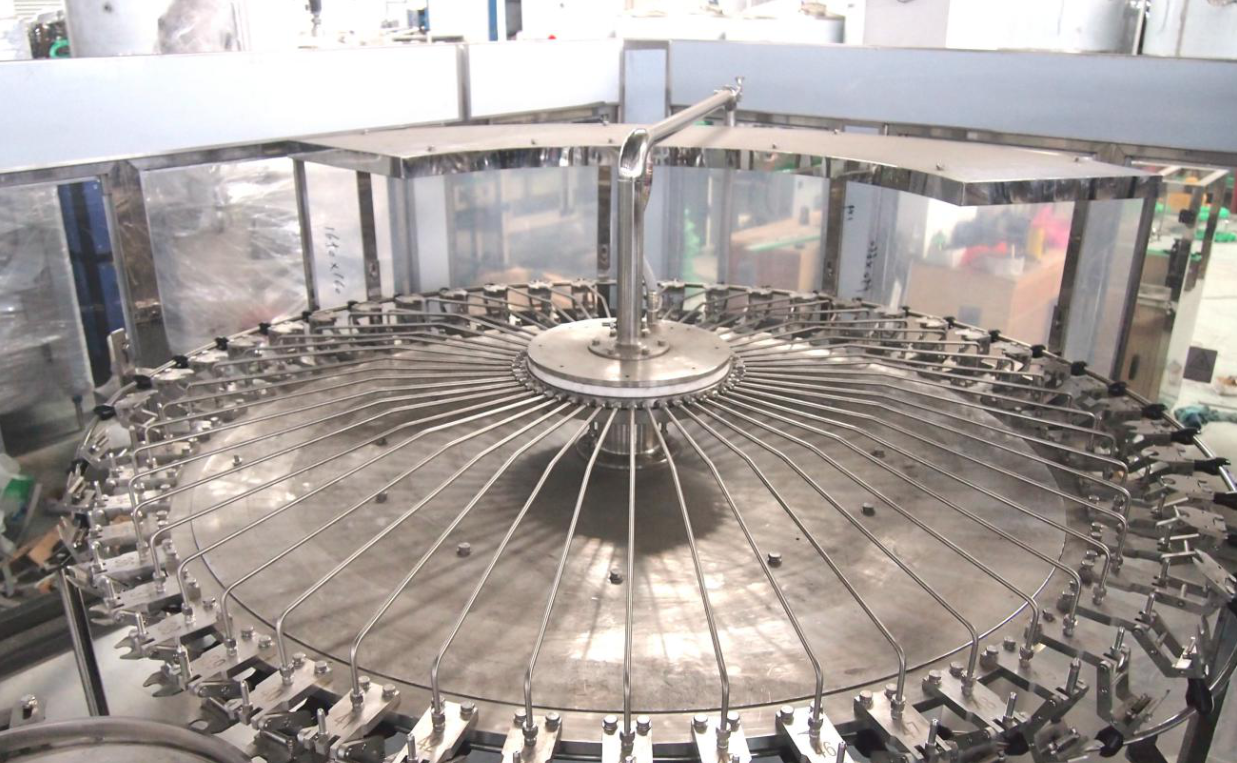

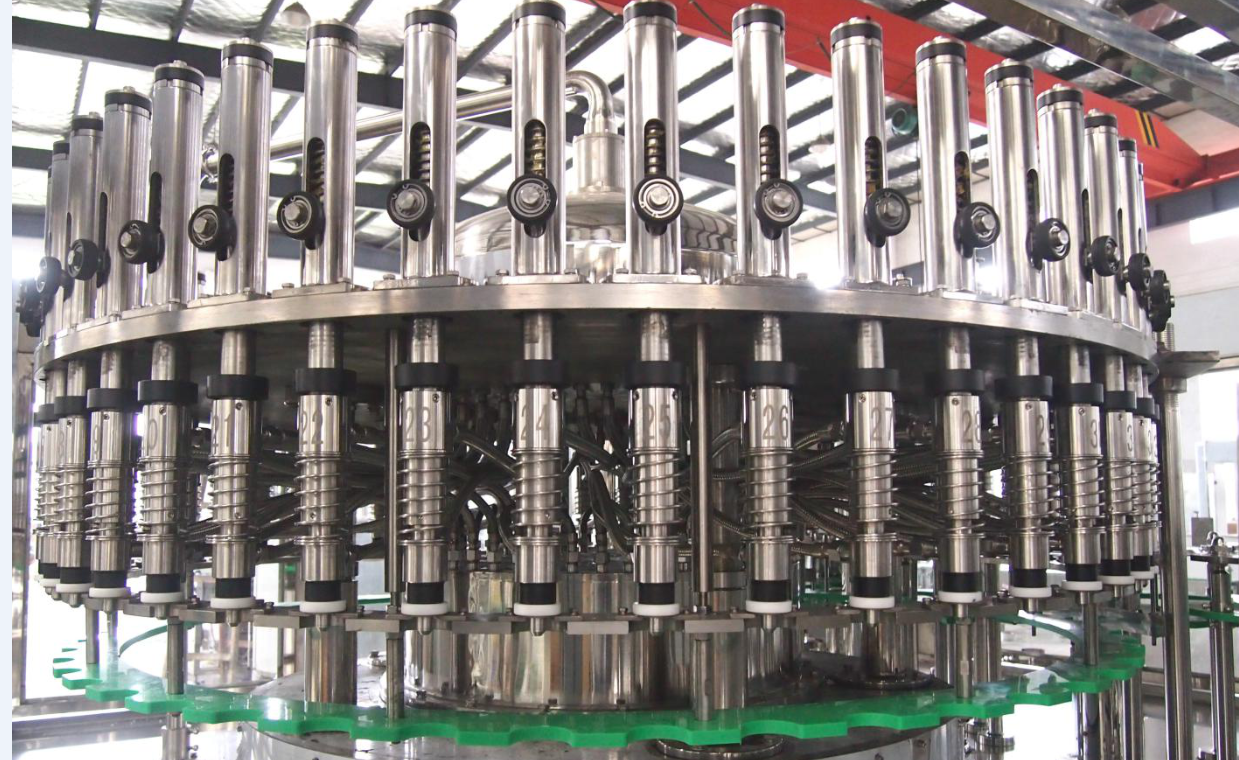

Detailed Photos of Mineral Water Bottle Filling Plant

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, Plastic Bottle Blowing Machine, Water Treatment system, water Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Filling Machine > Water Filling Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now