Product Description

This drinking water Bottle Making Machine used for PET water bottle, hot-fill bottle, CSD drinking, oil and pesticide bottle.

Adopt full servo control system (clamping servo, stretching servo, transfer preform servo, separating preform servo), makes structure stable and reliable. Also with high -speed and smooth easy maintenance advantage. Mold installation is very flexible which can meet the needs of non-stop online production. It has 4/5/6cavity, the production from 6000-9000pcs/hr. Same machine size and structure for different bottle scale volume.

Drinking Water Bottle Making Machine Feature

Feeding system

- Continous and high speed preform feeding system.

- Multiple protection device for precise preform feeding.

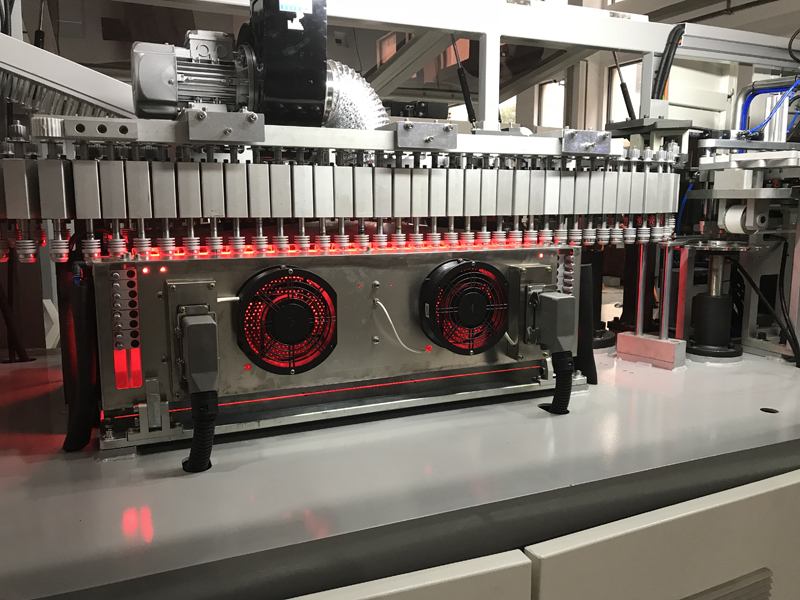

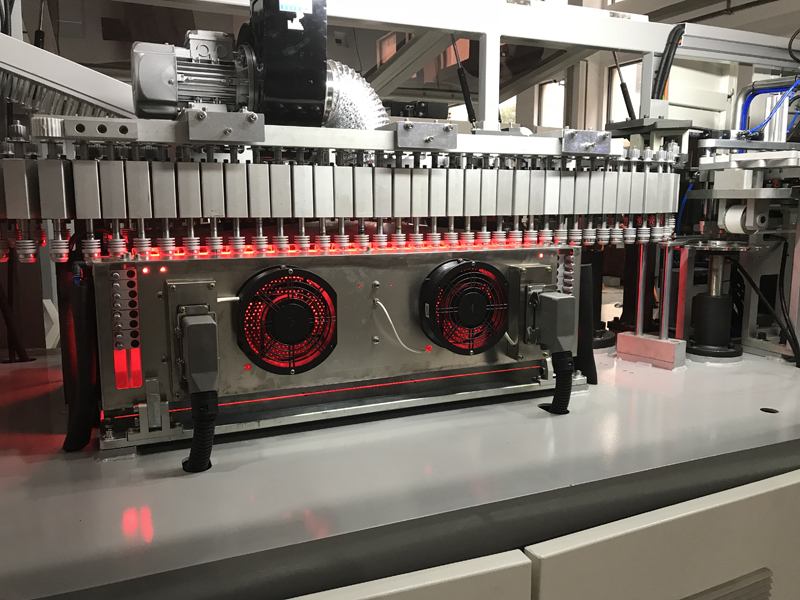

Transfer and heating system

- Horizontal rotation transfer system to eliminate preform flipping.

- Compact preform-chain base design for efficient heating and reduce energy consumption

- Optimized exhausting and preform surface cooling system.

- Infrared heat sensor for preform temperature monitoring

- Heating tunnel can inverse when changing the lamps

Transfer and taking preform system

- Servo motor drive preform transfer system for quick transfer and precise preform locating.

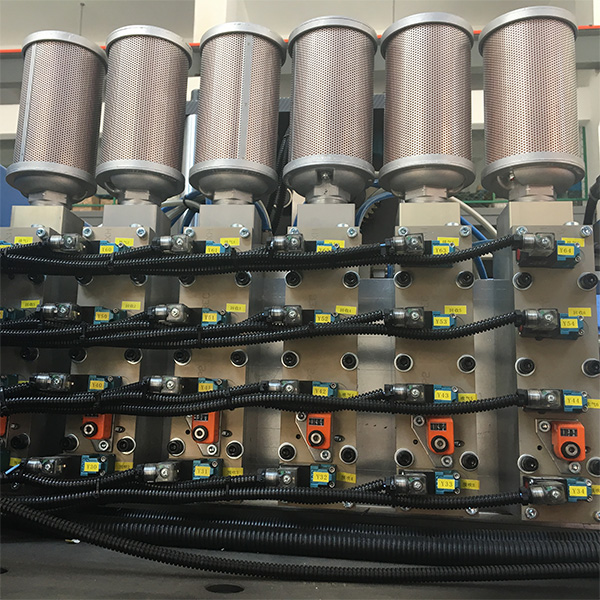

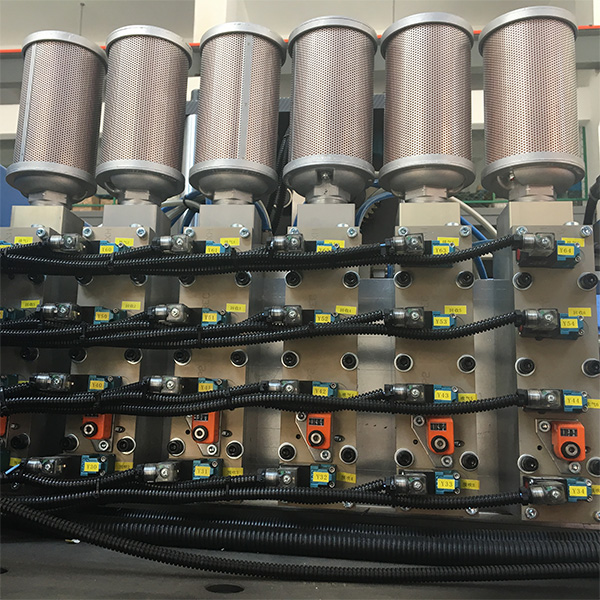

Blowing and clamping system

- Servo motor drive system with synchronized base blow mold for fast response operation.

- Precision electromagnetic valves for fast responding time and high production.

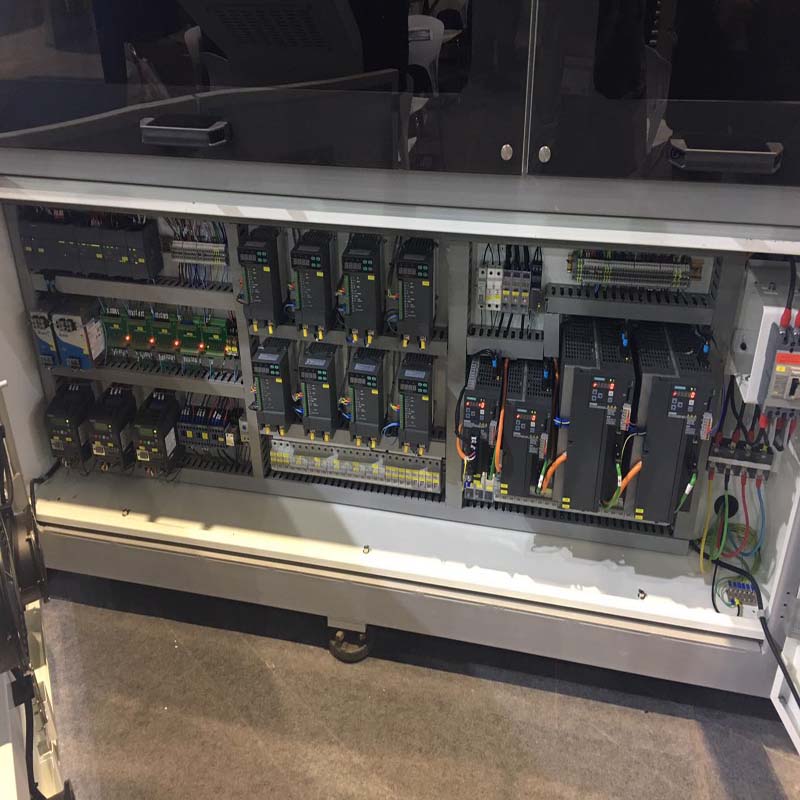

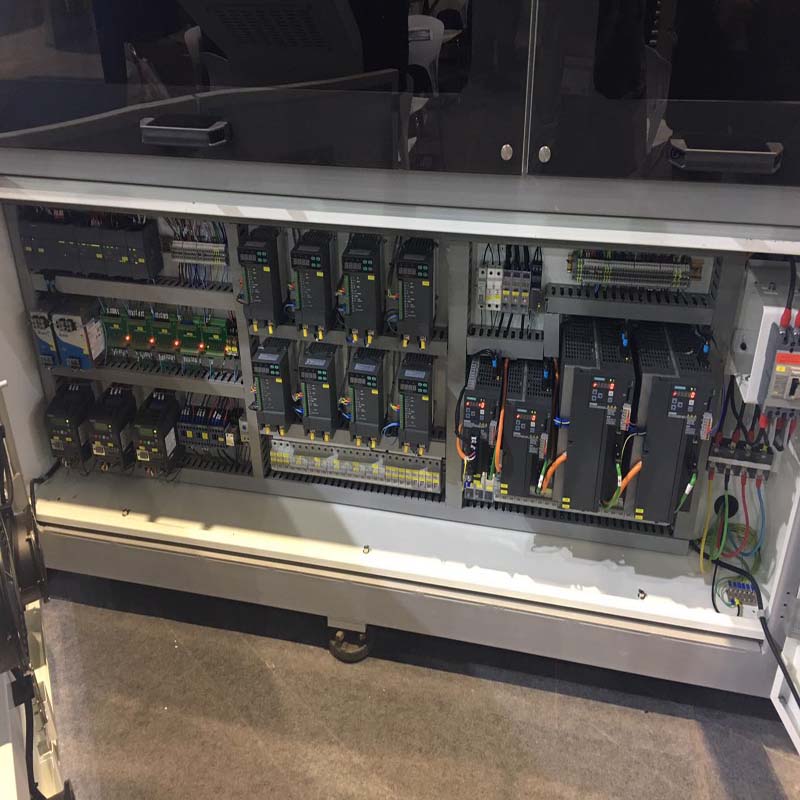

Control system

- Touch panel control system for simple operation.

- 10 inch touch screen with 64K colors.

Others

- All electric mechanism to ensure high-speed operation and precise locating.

- With quick mould change design.

- Low energy consumption, low wear, low pollution.

Technical Paramater

| Model | | UNIT | AL-TP4 | AL-TP5 | AL-TP5N | AL-TP6M |

| CONTAINER | Number of Cavity | PCS | 4 | 5 | 5 | 6 |

| Max. Capacity | L | 2.5 | 1.5 | 1.5 | 30 |

| Max. Neck Diameter | mm | 30 | 30 | 38 | 30 |

| Max. Body Diameter | mm | 110 | 95 | 95 | 80 |

| Max. Bottle Height | mm | 350 | 350 | 350 | 300 |

| Theoretical Output | B.P.H | 6000 | 8000 | 8000 | 9000 |

| MOLDING | Spindle Chain Pitch | mm | 38.1 | 38.1 | 50.8 | 38.1 |

| Cavity Pitch | mm | 120 | 105 | 105 | 90 |

| ELECTRICAL | Max. Heating Power | KW | 50 | 40 | 40 | 40 |

| Servo Motor Power | KW | 9.75 | 9.75 | 9.75 | 9.75 |

| Other Motor Power | KW | 4.21 | 4.21 | 4.21 | 4.21 |

| Total Power | KW | 63 | 54 | 54 | 54 |

| Voltage Frequency | V/HZ | 380V+/-10% 50HZ/220V+/-10% 60HZ |

| AIR SYSTEM | Blowing Pressure | Bar | 35 | 35 | 35 | 35 |

| High Pressure consuming | L/Min | 10000 | 8500 | 8500 | 7000 |

| WATER CHILLER | Pressure | Mpa | 3-5 | 3-5 | 3-5 | 3-5 |

| Temperature Range | ℃ | 10-12 | 10-12 | 10-12 | 10-12 |

| Flow Rate | L/Min | 50 | 50 | 50 | 50 |

| Cooling capacity | HP | 5 | 5 | 5 | 5 |

| MACHINE DIMENSION | Size(L*W*H) | M | 4*1.3*2.3 | 4*1.3*2.3 | 4*1.3*2.3 | 4*1.3*2.3 |

| Weight | KG | 4300 | 4300 | 4300 | 430 0 |

Drinking Water Bottle Making Machine Photo

Small Size, Occupy small Space

Independent valve control, use the world best SEITZ Brand

Adopt all imported valve, electric parts and motors

About us

We have more than 20 years knowledge and experience on PET Water Production Line. Our exporting product includes: Injection molding machine, Pet Preform Mould, stretch blow molding machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > High Speed Bottle Blowing Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now