Product Description

Automatic soda Filling Machine is mainly applied for filling drinks. It combines rinsing bottle, filling and capping into one machine. The full procedure is automatics. It is suitable for PET Bottle and plastic bottle to fill juice, mineral water, pure water. If add temperature control device, even can for hot filling. The adjustment for bottle type of each unit is fulfilled by turning handle. It is simple, easy and quick. The filling method applies new micro pressure filling so that the filling speed becomes more quick and stable. Compared with similar machines, it has higher output and more benefit.

Features

- The Carbonated Filling Machine adopts technology of air conveyor direct connect with bottle infeed of screw and conveyor. Easy to change bottle size.

- Adopt neck handling technology to convey bottles, no need to adjust the height of equipment and only need to change some spare parts.

- Washing-filling-capping transfer stably.

- Specially designed stainless steel bottle gripper does not touch the thread parts of bottle neck, avoiding the second contamination.

- High speed and mass flow filling valves.

- Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

- The electric system is from international brand and achieves the national food hygienic standard.

- The bottle out startwheel is helical structure. While changing over bottle size, it is no need to adjust bottle-out conveyor.

Technical Parameter

| Model | DCGF 32-32-10 |

| Washing workstation | 32 |

| Filling workstation | 32 |

| Capping workstation | 10 |

| Production capacity(500ml)(B/H) | 10000 |

| Bottle specification(mm) | Φ=50-95, H=150-310 |

| Motor power(KW) | 6.2 |

| Overall dimension(mm) | 4160×2690×2250 |

| Weight(kg) | 6000 |

Other models

| Model | Washig heads | Filling heads | Capping heads | Production B/H |

| DCGF14125 | 14 | 12 | 5 | 2000 |

| DCGF16166 | 16 | 16 | 6 | 3500 |

| DCGF18186 | 18 | 18 | 6 | 5000 |

| DCGF24248 | 24 | 24 | 8 | 7000 |

| DCGF404012 | 40 | 40 | 12 | 8000-10000 |

| DCGF505012 | 50 | 50 | 12 | 10000-12000 |

| DCGF606015 | 60 | 60 | 15 | 12000-15000 |

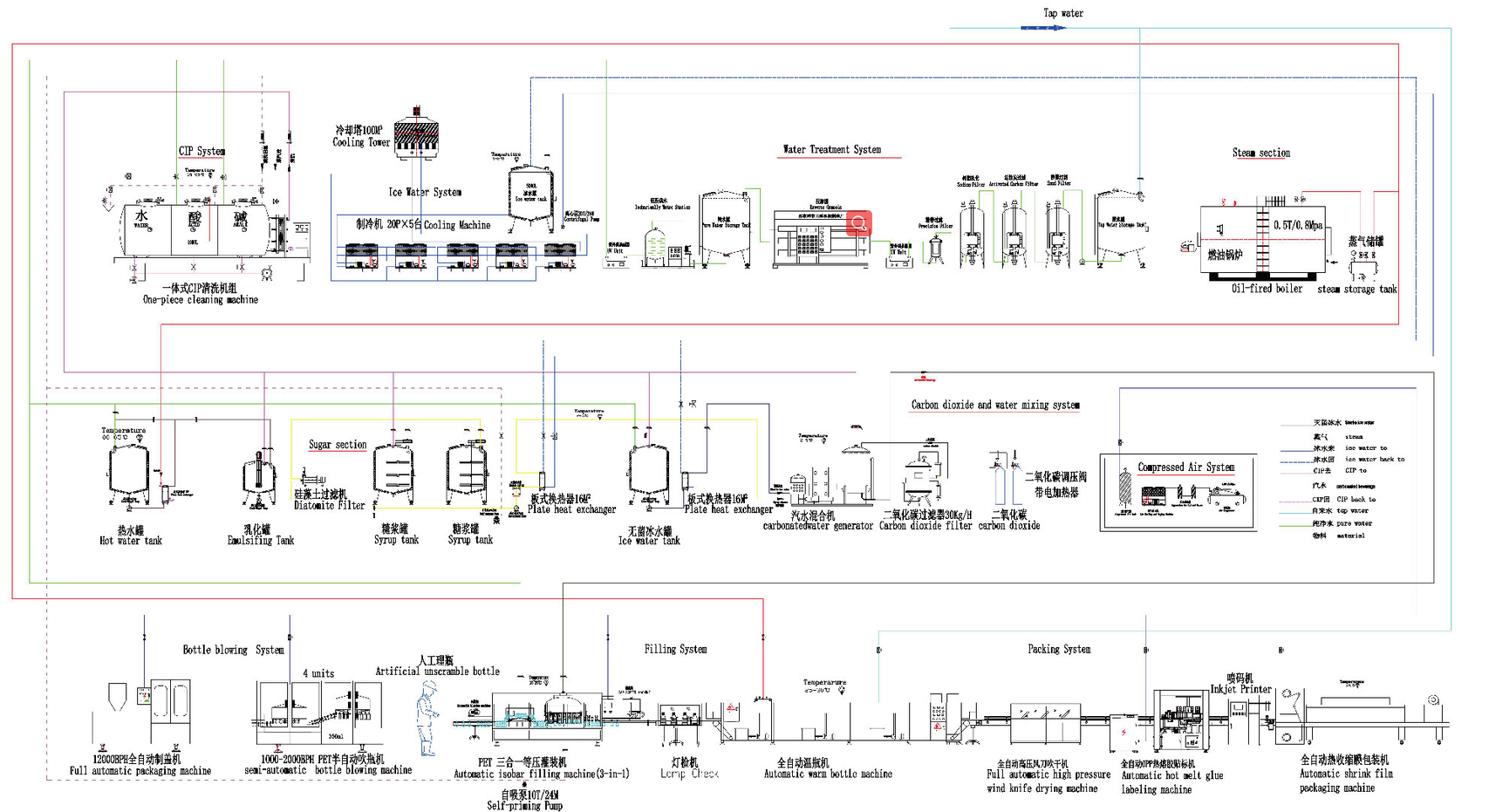

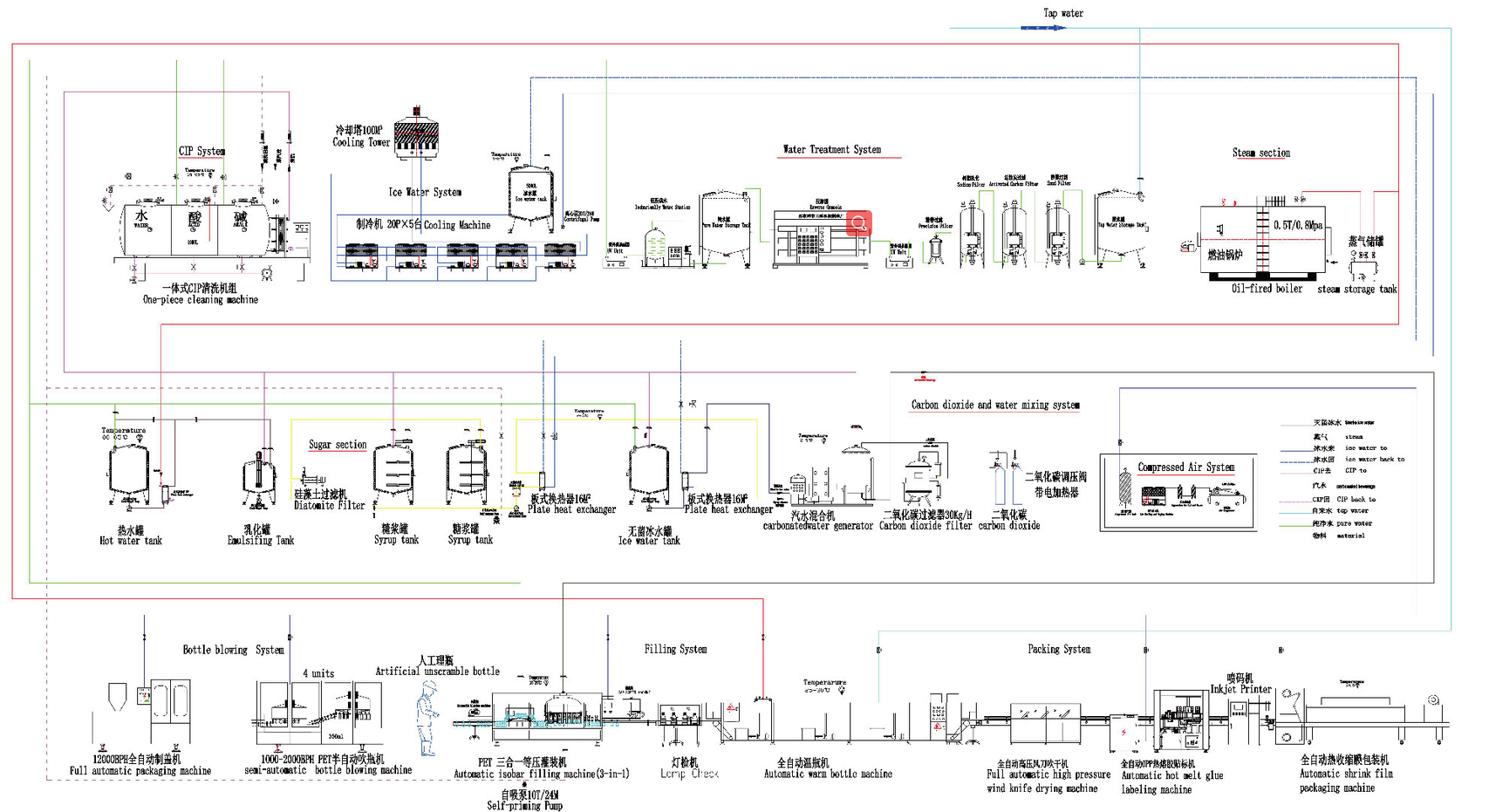

Flow Chart of Carbonated Drinks Filling Machine

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, Plastic Bottle Blowing Machine, Water Treatment system, carbonated filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Filling Machine > Carbonated Drinks Filling Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now