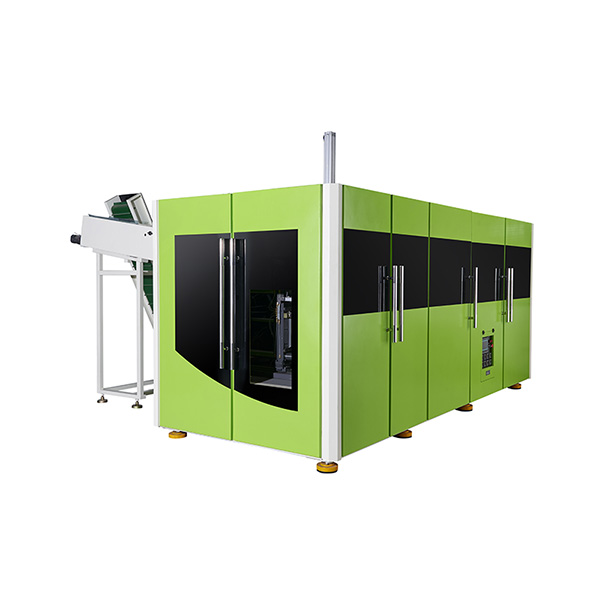

Product Description

Winiber is a professional solution supplier for the complete bottle blowing lines and water filling lines. Start from the raw material to the water bottle.

PET injection machine+Pet Preform Mould+auxiliary machine=Preform

Preform+Bottle Blowing Making Machine+auxiliary machine=Bottle

Water Treatment system+Bottle+Water Filling Machine+Labeling Machine+Packing Machine=Water Bottle

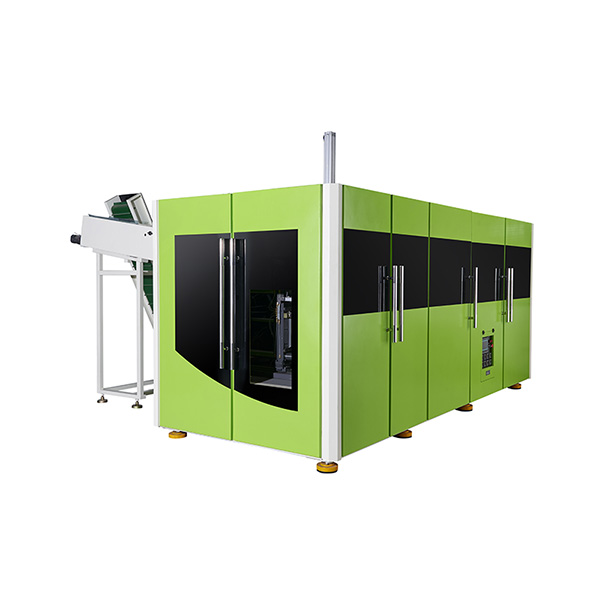

Bottle Blowing Making Machine Feature

- Man-machine interface control, easy to operate.

- Connecting rod automatic lubrication oil device protects the machine well.

- Shifting servo motor is more accurate and faster.

- Fast Speed, accurate position, smooth action.

- According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustable according to the bottle size to save time.

- Far infrared heater lamps have strong penetrations, preform are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group temperature separately.

- particular pre-heater design makes preform close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

- The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

- Reliable and special single valve design make all the air system clear.

Technical Parameter

| ITEM | UNIT | WBB-3S | WBB-4S | WBB-6S |

| PRODUCT | Theoretical output | Pcs/hr | 4500 | 5500 | 6500 |

| Max. Volume | L | 2 | 2 | 2 |

| Max. Height | MM | 360 | 360 | 360 |

| Max. Diameter | MM | 105 | 105 | 105 |

| MOLDING | Number of Cavities | / | 3 | 4 | 6 |

| Mould Plate Dimension(L×H) | MM | 430×360 | 600×360 | 840×360 |

| Mould Thickness | MM | 188 | 188 | 198 |

| Mould Opening Stroke | MM | 110 | 110 | 110 |

| ELECTRICAL | Power |

| 220-380V/50-60HZ | 220-380V/50-60HZ | 220-380V/50-60HZ |

| Total Power | KW | 18 | 25 | 35 |

| Heating Power | KW | 15 | 22 | 32 |

| AIR SYSTEM | Operation Pressure | Mpa | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 |

| Action Air Consuming | M³/min | ≥1.6 | ≥1.6 | ≥1.6 |

| Blowing Pressure | MPA | 2.6-4.0 | 2.6-4.0 | 2.6-4.0 |

| Blowing Air Consuming | M³/min | ≥3.2 | ≥4.8 | ≥4.8 |

| MACHINE | Main Body Dimension(L×W×H) | M | 2.7×1.45×2.05 | 3.4×1.9×2.05 | 4.5×1.9×2.0 |

| Main Body Weight | KG | 2300 | 2600 | 3200 |

| Preform Autoloader (L×W×H) | M | 1.9×1.9×2.2 | 1.9×1.9×2.2 | 2.1×1.9×2.4 |

| Preform Autoloader Weight | KG | 200 | 200 | 300 |

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET Preform Mould, Pet Blow Moulding Machine, Water treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Automaic Bottle Blowing Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now